PDP

Partner Perspectives

December 22, 2025

Building energy efficiency into new dairy facilities

By FOCUS ON ENERGY®

When building a new dairy barn or milking parlor, each decision can impact long-term operating costs and your bottom line. Incorporating energy-efficient equipment reduces utility bills and improves cow comfort. Below are sustainable tips to help farmers when planning new construction projects.

Lighting

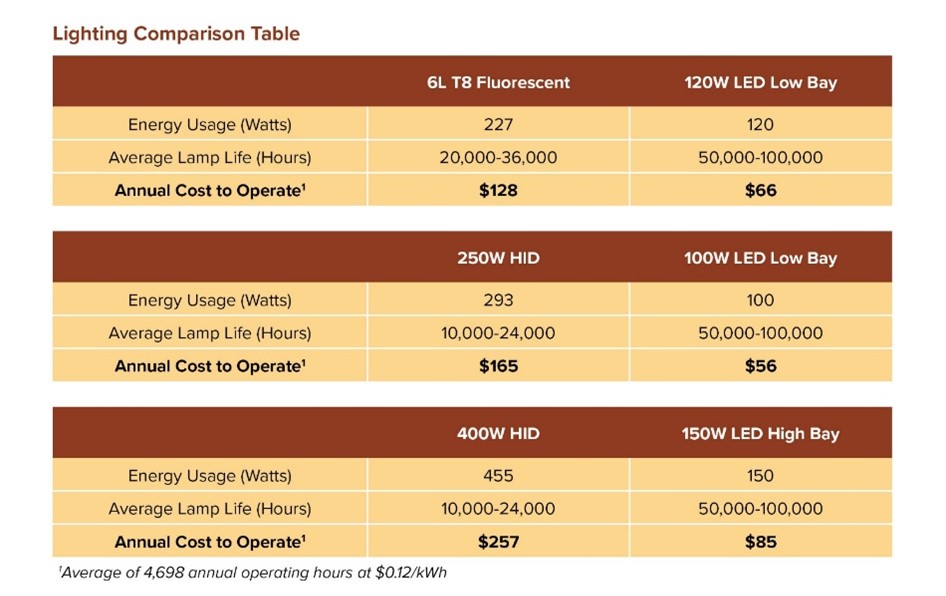

LEDs are a practical option for lighting agricultural facilities. Compared to traditional lamps like fluorescent or metal halides, LEDs use less energy and last longer. The Lighting Comparison Table below shows the cost of installing LEDs compared to other types of lamps.

LEDs can increase milk production by efficiently providing 16+ hours of light per day. Dimmable options allow for the necessary rest (6-8 hours) and flexibility for safely completing other farm tasks. Controls, such as timers and motion sensors, are a great option to use lights only when needed or in low-traffic areas. Farms can also integrate natural lighting strategies, such as skylights or translucent panels, to reduce the reliance on artificial lighting.

Ventilation systems

Regulating air quality will help eliminate the risk of airborne disease and is crucial for cow health and comfort. Farmers can work with a professional to design a system for adequate air quality and temperature control. These professionals can identify the types of fans needed and help with the design and layout, making the facility as efficient as possible.

Variable speed drives automatically adjust fans to temperature and humidity changes, preventing unnecessary use during cooler periods. Drives on motors and fans regulate airflow and ventilation using sensors. Positioning fans and checking alignment will also provide maximum efficiency.

Dairy equipment

Milk cooling accounts for a substantial portion of dairy farm costs. Pre-coolers, such as plate coolers, use well water to pre-cool milk before refrigeration, reducing compressor load. Refrigeration heat recovery systems can capture the waste heat and use it to preheat water for cleaning milking equipment, lowering heating costs.

Condensing units, or chillers, cool milk for storage or for direct loading. Previously, reciprocating compressors were used to cool milk. Now, scroll compressors are used, which are 15 to 20% more efficient. A well-maintained condensing unit can save money by replacing the compressor instead of the entire unit.

Beyond milk cooling, installing variable frequency drives (VFDs) on vacuum and milk pumps allows motors to operate at the speed needed. This reduces energy use during milking without sacrificing performance. Unlike traditional pumps operating at full speed, VFD technology adjusts to demand, lowering electricity and extending equipment life.

Livestock waterers are also more efficient. Newer waterers feature improved insulation to reduce heat loss and lower energy use, helping prevent freezing. Today’s models can cut water-heating energy costs by 20 to 80%. Heated waterers should be sized appropriately for the herd’s needs.

Planning ahead

Before construction begins, an energy assessment can pinpoint the biggest opportunities for savings. Many utilities and state programs offer financial rebates or incentives for installing energy-efficient equipment, which offsets upfront costs.

Pursuing energy efficiency is an investment with long-term benefits. By prioritizing lighting, fans, and other dairy equipment, farmers can build facilities ready for the future.

FOCUS ON ENERGY® is Wisconsin utilities' statewide energy efficiency and renewable resource program funded by the state's investor-owned energy utilities and participating municipal and electric cooperative utilities. For more information, call 800.762.7077 or visit focusonenergy.com. Focus on Energy is a Corporate Partner of Professional Dairy Producers®.